Contents:

Industry 4.0, or the Fourth Industrial Revolution, represents a major shift in how manufacturing processes are conceived and implemented. This revolution is not just a transition to new technologies—it is a comprehensive transformation of manufacturing that spans everything from core operations to strategic planning.

Industry 4.0 is based on the digitization of production processes and their comprehensive integration. This means all phases of production—from design to the final product—are executed digitally and connected into a unified system. The processes are so integrated that they can communicate and coordinate without human intervention.

This integration and digitization allow manufacturing to become more flexible, efficient, and transparent. Production processes can quickly adapt to market changes, be optimized to reduce costs and resources, and be tracked in real-time to ensure quality and consistency.

Industry 4.0 also enables better production management through the collection, analysis, and utilization of large volumes of data. This data helps identify issues, predict trends, optimize processes, and make better strategic decisions.

Ultimately, Industry 4.0 is not just about manufacturing—it’s also about people. While digitization and automation may reduce the need for some traditional jobs, they also create new opportunities for those who are willing and able to learn new skills and adapt to new technologies.

2. Development Steps from Industry 1.0 to Industry 4.0

The development of the industrial revolution occurred in several waves, shaping today's Industry 4.0. Understanding these phases helps us better comprehend the current context and direction of future development.

The first industrial revolution began with the introduction of mechanical production powered by water and steam. This period marked a transition from manual production to mechanized methods, primarily in the textile industry.

The second industrial revolution brought mass production and assembly lines, with electricity becoming the dominant power source. This era was also marked by the development of railways and telegraph networks, which improved communication and distribution.

Often referred to as the digital revolution, Industry 3.0 introduced widespread use of electronics and information technology in manufacturing. This led to automation, increased efficiency, and better quality control. The era saw the rise of computers, the internet, and other digital technologies.

2.4 Industry 4.0: The Fourth Industrial Revolution (21st Century)

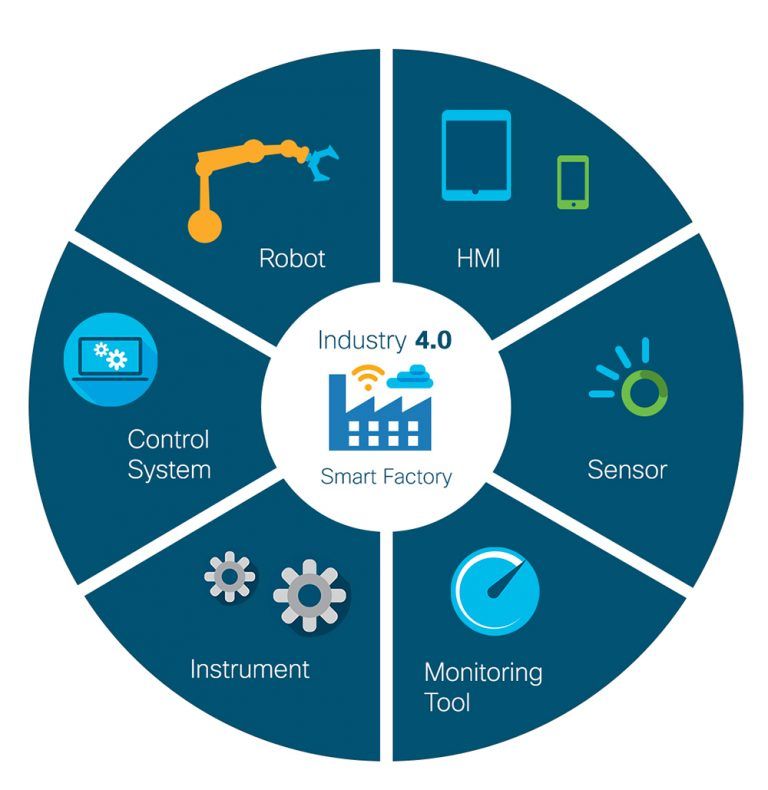

Industry 4.0 is founded on digitization, automation, connectivity, and data analysis. Key technologies include IoT, Big Data, AI, machine learning, advanced robotics, 3D printing, augmented reality, and more. The goal is to create "smart factories" that are flexible, efficient, and capable of personalized mass production.

Each industrial revolution has introduced new technologies and methods that transformed production, increased productivity, and changed society. Although each brought challenges, they also opened doors for innovation and progress.

The Internet of Things refers to the interconnection of various devices via the internet. These devices—machines, sensors, cameras, computers—communicate and exchange data. In manufacturing, IoT can track machine conditions in real-time, detect and fix problems quickly, and optimize processes by reducing downtime and improving efficiency.

Big Data refers to data sets too large for traditional processing methods. These data come from various sources like machines, sensors, logistics systems, and social media. Advanced analytics allows for deeper insights into production, pattern identification, trend prediction, maintenance planning, and resource optimization.

AI and ML enable computers to learn and make decisions based on data. In Industry 4.0, these technologies automate complex processes, detect anomalies, support predictive maintenance, and personalize products. AI processes large datasets faster and more accurately than humans, and ML allows systems to improve over time through experience.

CPS integrate computer networks, physical processes, and human interaction. In manufacturing, CPS bridges digital and physical systems, enabling real-time feedback, improved control, and production optimization.

Autonomous robots operate without human input using AI and sensors to navigate and interact with their environment. In Industry 4.0, robots perform not only repetitive but also complex tasks like assembly and maintenance. They offer greater production flexibility by being easily reprogrammable.

Additive manufacturing creates objects layer by layer from digital models. It enables high-precision, complex part production and design flexibility. In Industry 4.0, it is used for prototyping, custom parts, and small-batch manufacturing.

AR overlays digital content onto the real world, often through smartphones or smart glasses. In manufacturing, AR aids in training, remote assistance, product design, and maintenance—for example, guiding workers through assembly with real-time visuals.

Cloud computing provides online access to computing resources, enabling storage, data processing, and powerful tools like analytics and AI. In Industry 4.0, it supports fast deployment, system integration, and collaboration across locations.

Horizontal integration connects systems on the same production level (e.g., multiple lines or plants), while vertical integration links all production phases from procurement to sales. This creates flexible, integrated systems that react quickly to market demands and improve resource efficiency and quality control.

Each of these pillars is powerful individually, but their real value lies in integration. Together, they enable intelligent, efficient, and innovative manufacturing systems.

Contents:

Industry 4.0, or the Fourth Industrial Revolution, represents a major shift in how manufacturing processes are conceived and implemented. This revolution is not just about transitioning to new technologies, but a comprehensive transformation of manufacturing covering everything from basic operations to strategic planning.

Industry 4.0 is based on the digitalization of production processes and their comprehensive integration. This means that all stages of production—from design to final product—are performed digitally and integrated into a unified system. Processes are so interconnected that they can communicate and coordinate their activities without human intervention.

This integration and digitalization allow production to be more flexible, efficient, and transparent. Manufacturing processes can quickly adapt to market changes, optimize to reduce costs and resource use, and be monitored in real time to ensure quality and consistency.

Industry 4.0 also enables better production management through the collection, analysis, and utilization of large volumes of data. This data can help identify problems, predict trends, optimize processes, and make better strategic decisions.

Ultimately, Industry 4.0 is not just about production, but also about people. While digitalization and automation may reduce the need for some traditional jobs, they also create new opportunities for those willing and able to learn new skills and adapt to new technologies.

2. Development Steps from Industry 1.0 to Industry 4.0

With the development of the industrial revolution came a series of shifts that shaped today's Industry 4.0. Understanding these steps can help us better grasp the current context and the direction of future development.

The First Industrial Revolution began with the mechanization of production, using water and steam power. This era marked the transition from manual labor to mechanized methods, primarily in the textile industry.

The Second Industrial Revolution introduced mass production and assembly lines, with electricity as the dominant power source. This period was also marked by the development of railroads and telegraph networks, enabling better communication and distribution.

Often called the Digital Revolution, the Third Industrial Revolution brought widespread use of electronics and information technology in manufacturing. It enabled automation, improved efficiency, and better quality control. This era saw the rise of computers, the internet, and other digital technologies.

2.4 Industry 4.0: The Fourth Industrial Revolution (21st century)

Industry 4.0 is based on digitalization, automation, connectivity, and data analysis in production. Key technologies include the Internet of Things (IoT), big data, artificial intelligence, machine learning, advanced robotics, 3D printing, augmented reality, and more. The goal is to create “smart factories” that are flexible, efficient, and capable of large-scale product personalization.

Each industrial revolution introduced new technologies and methods that transformed production, increased productivity, and reshaped society in different ways. Though each revolution brought its own challenges, they also unlocked opportunities for innovation and progress.

Industry 4.0 relies on the convergence of several key technologies that enable digitalization, automation, connectivity, and analysis in manufacturing.

The Internet of Things refers to the connectivity of various devices via the internet. These devices—which can include machines, sensors, cameras, computers, and other equipment—communicate and exchange data over a network. IoT transforms manufacturing by enabling real-time condition monitoring of machines, quick problem detection, and process optimization that reduces downtime and boosts efficiency.

Big Data involves massive volumes of data that are too large for traditional processing methods. This data comes from machines, sensors, logistics systems, social media, and more. With advanced analytics, this information can reveal deep insights into production processes, identify patterns and trends, predict maintenance needs, and optimize resource use.

AI and ML enable computers to learn and make decisions based on data analysis. In Industry 4.0, these technologies automate complex processes, detect anomalies, enable predictive maintenance, and support product personalization. AI analyzes large data volumes faster and more accurately than humans, while ML allows systems to improve autonomously through experience.

Cyber-physical systems integrate computer networks, physical processes, and human users. In Industry 4.0, CPS enables deep integration between digital technologies and physical manufacturing processes, allowing digital information to directly influence physical operations for better control and optimization.

Autonomous robots perform tasks without human intervention, using AI and sensors to navigate and interact with their environment. In Industry 4.0, robots handle not only repetitive tasks but also complex operations such as assembly, inspection, and maintenance. Advanced robotics increases flexibility, as robots can be reprogrammed quickly for different tasks.

Additive manufacturing, or 3D printing, builds objects layer by layer from digital models. This technology allows the creation of complex parts with high precision and design flexibility. In Industry 4.0, 3D printing is used for prototyping, custom part production, and even mass manufacturing of specific products.

Augmented reality is a technology that overlays digital information on the real world, often using a smartphone camera or special glasses. In Industry 4.0, AR is used for worker training, remote support, product design, and maintenance. For example, a worker can wear AR glasses that display step-by-step instructions or diagnostics in real-time.

Cloud computing refers to using computing resources via the internet rather than relying on local hardware. The cloud allows for storage and processing of large volumes of data and provides access to advanced tools for analytics, AI, and more. In Industry 4.0, cloud computing enables rapid implementation of new applications, integration across systems, and collaboration across locations and organizations.

Horizontal integration connects systems at the same production level—such as various production lines or plants. Vertical integration links different production stages, from procurement to sales and distribution. In Industry 4.0, these integrations create highly adaptable and coordinated systems. For example, a change in market demand can be quickly communicated from sales to procurement and production, allowing fast adaptation and better resource utilization.

Each of these technological pillars is crucial to Industry 4.0, but their true power lies in their integration. When implemented correctly, they create intelligent, efficient, flexible, and transparent systems—opening opportunities for innovation and competitive advantage.

As Industry 4.0 evolves, its impact on businesses and workers continues to grow. These changes bring both opportunities and challenges that require strategic planning.

Industry 4.0 offers businesses new opportunities to improve efficiency, reduce costs, and enhance product quality. IoT and Big Data offer insights into production, consumer trends, and market conditions, enabling better decision-making. It also enables new business models—such as personalized mass production and servitization (offering services rather than just products).

However, it also brings challenges, including high investment costs, data security issues, and regulatory or ethical dilemmas (especially around AI and data privacy).

Workers may benefit from safer, less repetitive work and new roles in data analysis, robotics, or cybersecurity. But automation may reduce demand for low-skilled jobs, requiring workers to upskill. Remote work and digital workflows may also affect work-life balance and mental health, highlighting the importance of training, education, and social protection.

Industry 4.0 is transforming manufacturing processes from operational efficiency to product quality and flexibility. Key changes include:

Robots, autonomous systems, and AI boost productivity, reduce errors, increase production speed, and support continuous operations.

Thanks to digital tools, companies can now produce tailored products on a scalable and cost-effective basis, meeting individual customer needs and unlocking new market segments.

With sensors, IoT, and big data, companies can detect quality issues in real time—reducing waste, improving products, and increasing customer satisfaction.

Digitalized systems let companies respond rapidly to market shifts, new products, or changes in demand. This helps them stay competitive in a fast-changing world.

Key benefits of adopting Industry 4.0 in manufacturing include:

Automation, machine learning, and cyber-physical systems optimize production, cut downtime, and improve overall productivity.

Real-time monitoring and automated quality checks reduce defects before products reach the customer.

Faster adaptation of product lines and production models reduces risk and increases responsiveness.

3D printing and IoT support on-demand manufacturing of customized products.

Robots can handle dangerous tasks, reducing the risk of injury for human workers.

Big Data and analytics offer deeper insights into operations and trends, empowering faster and smarter decisions.

Despite the advantages, companies may face several hurdles:

Implementing new technologies can be costly, especially for small and medium enterprises.

With increasing digitalization, cybersecurity and data protection become critical concerns.

There’s often a shortage of qualified professionals to manage AI, big data, and IoT systems.

As data collection grows, companies must comply with privacy laws and ethical standards.

Transitioning to Industry 4.0 requires organizational, cultural, and structural change—which demands strong leadership and planning.

Industry 4.0 is revolutionizing manufacturing. With strategic investment and proper implementation, its benefits—efficiency, flexibility, quality, and competitiveness—can outweigh the challenges and drive transformation suited for the digital age.